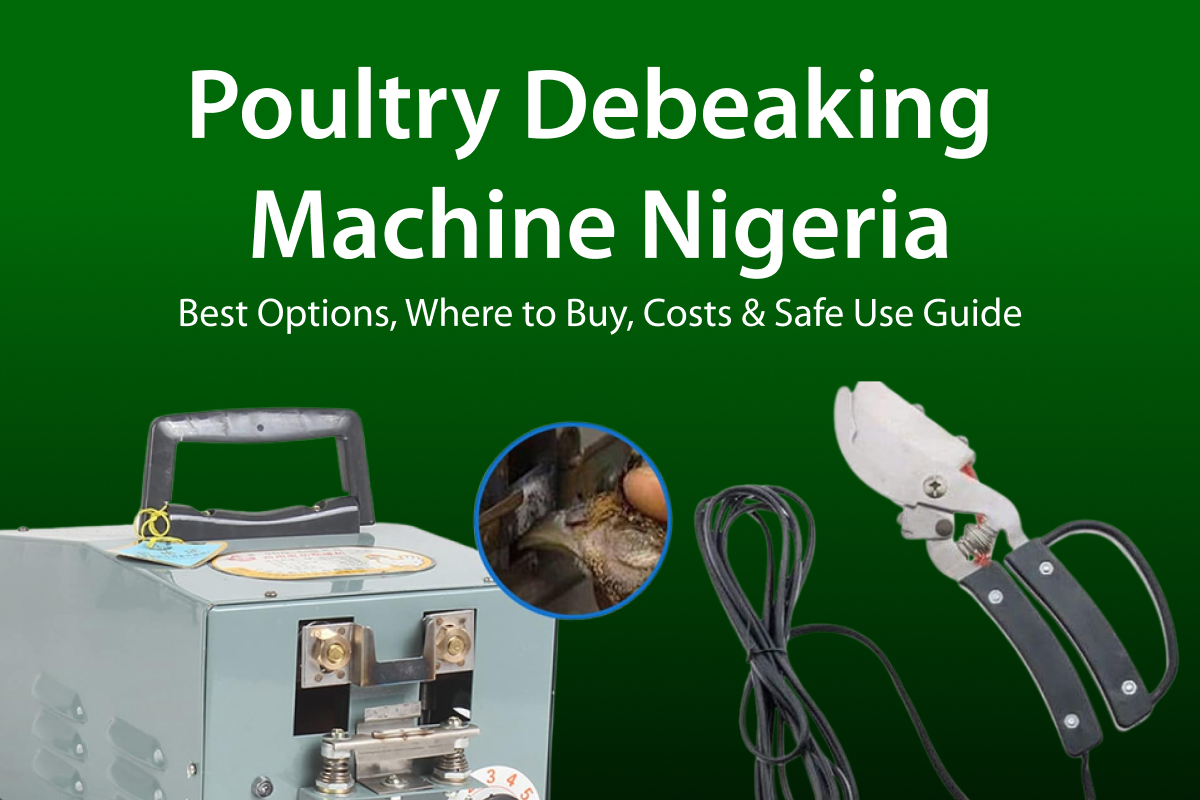

Poultry Debeaking Machine Nigeria: Best Options, Where to Buy, Costs

A poultry debeaking machine (beak trimmer) is a tool used to shorten or smooth the beaks of chickens to reduce injurious pecking and cannibalism. In Nigeria, you can choose between manual, electric, and automated industrial machines. Small-scale manual or hand-held electric units cost roughly ₦20,000–₦150,000, mid-range semi-automated kits ₦150,000–₦650,000, and full industrial automated systems ₦700,000–₦4,500,000+, depending on capacity and features. Buy from verified suppliers with after-sales support (installation, spare parts, training).

- Why farmers use debeaking machines

- Best debeaking machine options for Nigerian poultry farms

- Where to buy debeaking machines in Nigeria (including “near me” guidance)

- Top-rated automated debeaking machines for commercial use

- How to choose the right debeaking machine for broiler chickens

- Affordable suppliers and trusted manufacturers with after-sales service

- Electric vs Manual debeaking machine — side-by-side comparison

- User reviews snapshot (what farmers say)

- Cost ranges and budgeting for industrial systems

- Step-by-step safe guide to using a poultry debeaking machine

- Welfare, legal and ethical considerations

Why farmers use debeaking machines

Debeaking (also called beak trimming) is used to prevent severe pecking, cannibalism and feed waste in dense commercial flocks. When done correctly-minimally and early—beak trimming reduces injury and improves flock survival. Machines standardize the process and increase speed for large flocks.

Best debeaking machine options for Nigerian poultry farms

- Hand-held manual cutters (small farms)

Pros: Low cost, simple, no electricity.

Cons: Slower, requires steady technique, higher variability.

- Hand-held electric trimmers (small to medium)

Pros: Faster, cleaner cuts, portable.

Cons: Requires electricity or generator; maintenance of blades.

- Semi-automatic bench units (medium farms)

Pros: Repeatable cuts, higher throughput, adjustable settings.

Cons: Requires trained operator, electricity.

- Fully automated industrial debeakers (large commercial farms)

Pros: High throughput, consistent trimming, integrated with handling lines.

Cons: High capex, needs installation, spare parts and skilled tech support.

Where to buy debeaking machines in Nigeria (including “near me”)

How to find local suppliers fast:

Search Google Maps for “debeaking machine near me” + your city (e.g., “debeaking machine Ibadan”).

Check national agro marketplaces and product pages (Farmsquare.ng, Afrimash, Farmhouse suppliers).

Contact poultry equipment dealers in major hubs: Lagos, Ibadan, Kano, Kaduna, Port Harcourt, Abuja.

Ask poultry extension officers or local feedmillers – they often recommend trusted suppliers and technicians.

What to request from a supplier:

- Product datasheet and maintenance manual

- Warranty & spare parts availability

- On-site installation or remote setup guide

- Demo or video of the machine in use

- References from existing customers in Nigeria

Top-rated automated poultry debeaking machines for commercial use

(Representative features to look for – model names will vary by supplier)

- High throughput: 1,000–5,000 birds/hour.

- Adjustable trimming depth: to trim tip only, or partial beak as required.

- Bird-friendly handling: soft clamps, fast cycle to minimize stress.

- Integrated dust extraction: to manage beak dust and hygiene.

- PLC control & safety interlocks: reliable automation and operator safety.

- After-sales support: spare blades, on-site tech training, maintenance contracts.

How to choose the right debeaking machine for broiler chickens

Decision checklist

- Flock size & throughput needs: small (<1,000), medium (1,000–10,000), large (>10,000).

- Beak trim style: tip-trim vs partial-trim — choose machine with adjustable depth.

- Power availability: off-grid? consider solar-ready systems or manual options.

- Budget: include capex + spare parts + maintenance + training.

- Welfare & regulations: prefer machines that minimize stress and tissue damage.

- Supplier support: local technicians, spare parts stock, warranty length.

Example recommendation:

Small broiler grower (≤2,000 flock) → hand-held electric trimmer;

Medium (2,000–10,000) → semi-automatic bench unit;

Large commercial integrator → automated inline system with handling conveyor.

Affordable poultry debeaking machines suppliers in Nigeria & leading manufacturers

Where to source:

Local agro-equipment dealers in Lagos, Kano, Ibadan – they often stock hand-held and semi-automatic units. Specialized poultry equipment importers – can supply automated systems; ask for import paperwork and warranty. Direct from manufacturer (China/EU) – viable for industrial systems, but check logistics and local installation partner.

What makes a supplier reliable:

- Clear warranty (12 months minimum)

- Local spare parts availability

- Technicians who offer installation & training

- Positive user reviews and verified references

Recommendation: For most Nigerian broiler farmers scaling beyond small backyard operations, hand-held electric or semi-automated units give the best balance of cost and throughput.

We Handpicked These For You;

– Disinfectant Fogging Machine

User reviews of popular debeaking machines (summary)

What farmers praise: quick trimming, lower flock injuries post-trim, improved feed conversion when done correctly, and reduced labor time.

Common complaints: blades dulling quickly (if low-quality), lack of spare parts locally, inconsistent trimming depth on manual setups.

Actionable lesson: buy from suppliers who guarantee spare blades and provide local blade sharpening or replacements.

Cost of industrial debeaking machines for large-scale poultry farms (budget planning)

Estimated capital (2025, NGN, rough guide)

- Small hand-held electric kit: ₦25,000–₦120,000

- Semi-automatic bench unit: ₦150,000–₦650,000

- Automated inline industrial system: ₦700,000–₦4,500,000+ (depends on throughput and automation)

Other costs to budget: installation (₦20,000–₦150,000), shipping & import duties (if imported), spare blades (₦2,000–₦15,000 each), training (₦10,000–₦50,000).

Step-by-step guide to using a poultry debeaking machine safely (short, actionable steps)

Important: only trained staff should perform debeaking. Minimize stress, avoid excessive tissue removal, and adhere to welfare best practices.

Preparation

- Read the manual and check the machine’s condition (blades, guard, power).

- Sanitize blades and work area to reduce infection risk.

- Gather equipment: beak trimmer, calming pen, gloves, antiseptic spray, disinfectant.

Handling the birds

Work in pairs: one handler holds the bird, the other operates the trimmer.

Hold bird gently, secure head for a stable cut — minimal struggle.

Trim only the beak tip unless otherwise required by your vet (partial trim only).

Make quick, single cuts with the machine; avoid repeated cuts on same beak.

Aftercare

Observe birds post-trim for bleeding or abnormal behavior for 24-72 hours.

Apply an antiseptic if there’s any soft tissue damage.

Record batch data – date, operator, machine settings, and any issues.

Timing note: Best practice is to perform beak trimming early (day-old chicks or within first week) under veterinary advice to reduce long-term pain and stress.

Welfare, legal and ethical considerations

Minimize harm: Only perform beak trimming when necessary and follow minimal trimming guidelines.

Alternatives: environmental enrichment, lower stocking density, and breed selection also reduce pecking, sometimes eliminating the need for trimming.

Training: ensure operators are trained and supervised.

Regulatory: follow any national or regional animal welfare rules and industry guidelines.

Buying checklist – What to confirm before purchase

- Exact trim depth adjustments and calibration options

- Warranty & duration (12+ months ideal)

- Spare parts (blades, switches) and delivery time in Nigeria

- Local technical support and installation service availability

- Power requirement and compatibility with local electricity or solar kits

- Demonstration video or on-site demo offered by supplier

- Customer references and verified reviews

FAQs (Frequently Asked Questions)

Q: Where can I buy debeaking machines for poultry birds near me?

A: Search local agro-equipment suppliers in major hubs (Lagos, Kano, Ibadan), check Farmsquare’s equipment category, or search Google Maps for “poultry equipment supplier near me.” Ask for warranty and spare parts availability.

Q: How much does a poultry debeaking machine cost in Nigeria?

A: Small manual cutters start from ₦8,000. Hand-held electric units range ₦25,000-₦120,000. Semi-automatic and industrial machines range from ₦150,000 to several million naira depending on capacity.

Q: Is debeaking humane?

A: When performed minimally and early by trained staff, debeaking reduces severe pecking and mortality. However, welfare-focused alternatives (environmental enrichment, lower stocking densities) should be considered where feasible.

Q: Do I need after-sales service?

A: Yes — prioritize suppliers who provide spare parts, blade replacements, and technical support in Nigeria.

Looking for a reliable debeaking machine, spare parts, or installation support? Farmsquare supplies a range of poultry equipment for Nigerian farms — from budget hand tools to industrial automation.

- Shop now or request a quote: www.farmsquare.ng

- Call/WhatsApp: +237049089805, +2348133974376

Greenhouses

Greenhouses