Factory Equipments

Camry Spring Scale | 100kg | 120kg | 150kg

Price range: ₦65,000 through ₦69,000A 100kg spring scale is a type of scale that uses a spring to measure weight. It is frequently used in commercial and industrial settings because it is an easy and accurate way to measure weight.

BENEFITS

- They are relatively inexpensive.

- They are easy to use.

- They are reliable.

- They are durable.

Counter Flow Cooler (SKLN Series) -SKLN 16×16

Original price was: ₦3,900,000.₦3,170,000Current price is: ₦3,170,000.The counter flow counter, which is a Famsun Brand is cooling equipment, used to achieve ambient temperature +(3-5℃). The counter-flow cooler solutions ensure the correct temperature of pellets prior to storage.

The vertical cooler is suitable for optimum cooling of extruded or pelletized products based on customer applications and preferences. It prepares the pellets optimally for storage and is one of the cleanest solutions due to its discharge system.

Product Features and Specifications

- Main machine base

- Pellet distributor

Stainless steel for distribution mechanism - Vertical octagon cooling casing

- Stainless steel for the hood

- Discharging grid and hopper

- Cooling time: 10-15 mins

- Temperature after cooling: 3-5℃

Moisture reducing: ≥3% - Cooling air volume: 13500.00m3/h

- Power: 1.50kW.

- Brand: FAMSUN SKLN 16×16

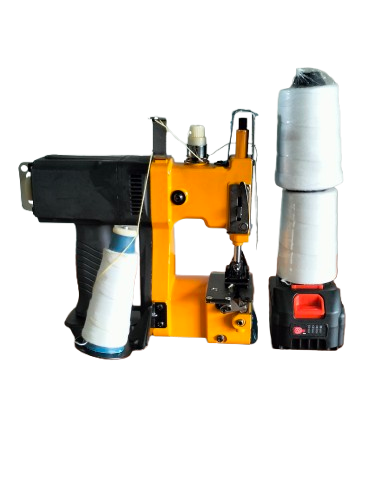

Sack Sewing Machine | Stitch Sacks or Bags

Original price was: ₦280,000.₦265,000Current price is: ₦265,000.A sack sewing machine is a specialized piece of equipment designed for stitching sacks or bags made of materials such as jute, burlap, polypropylene, and other woven fabrics. These machines are widely used in industries like agriculture, food packaging, and construction, where the need to pack and seal bulk items into sacks is essential. Sack sewing machines offer reliability, speed, and durability, making them ideal for high-volume packaging operations.

It is Capable of sewing through thick and durable materials like:

– Woven polypropylene (PP)

– High-density polyethylene (HDPE)

– Jute

– Sacks

– Multi-wall paper

STARCH LINE: Fully Automated End-End Cassava Starch Processing Plant

Fully Automated End-End Cassava Starch Processing Plant

The fully automated end-end cassava starch processing plant is used to process cassava tubers into high quality cassava starch, which is useful for both food and as raw materials for various industrial manufacturing purposes e.g. Sweetener, glucose, gum, paper, pharmaceutical, textiles etc.

This is capable of producing between 10-100 tons/day of high quality cassava starch depending on buyers’ size request specification. It is available on order from one of our partners (Niji lukas).

The plant integrates a mechanical peeler, grater, Mechanical sieve, hydro-cyclone, pile- centrifuge and flash dryer.